Published on Apr 02, 2024

Welding technology has obtained access virtually to every branch of manufacturing; to name a few bridges, ships, rail road equipments, building constructions, boilers, pressure vessels, pipe lines, automobiles, aircrafts, launch vehicles, and nuclear power plants. Especially in India, welding technology needs constant upgrading, particularly in field of industrial and power generation boilers, high voltage generation equipment and transformers and in nuclear aero-space industry.

Computers have already entered the field of welding and the situation today is that the welding engineer who has little or no computer skills will soon be hard-pressed to meet the welding challenges of our technological times. In order for the computer solution to be implemented, educational institutions cannot escape their share of responsibilities.

Automation and robotics are two closely related technologies. In an industrial context, we can define automation as a technology that is concerned with the use of mechanical, electronics and computer-based systems in the operation and control of production. Examples of this technology include transfer lines, mechanized assembly machines, feed back control systems, numerically controlled machine tools, and robots. Accordingly, robotics is a form of industrial automation.

There are three broad classes of industrial automation: fixed automaton, programmable automation, and flexible automation. Fixed automation is used when the volume of production is very high and it is therefore appropriate to design specialized equipment to process the product very efficiently and at high production rates. A good example of fixed automation can be found in the automobile industry, where highly integrated transfer lines consisting of several dozen work stations are used to perform machining operations on engine and transmission components.

The economics of fixed automation are such that the cost of the special equipment can be divided over a large number of units, and resulting unit cost are low relative to alternative methods of production. The risk encountered with fixed automation is this; since the initial investment cost is high, if the volume of production turns out to be lower than anticipated, then the unit costs become greater than anticipated. Another problem in fixed automation is that the equipment is specially designed to produce the one product, and after that products life cycle is finished, the equipment is likely to become obsolete. For products with short life cycle, the use of fixed automation represents a big gamble.

Programmable automation is used when the volume of production is relatively low and there are a variety of products to be made. In this case, the production equipment is designed to be adaptable to variations in product configuration. This adaptability feature is accomplished by operating the equipment under the control of "program" of instructions which has been prepared especially for the given product.

The program is read into the production equipment, and the equipment performs the particular sequence of processing operations to make that product. In terms of economics, the cost of programmable equipment can be spread over a large number of products even though the products are different. Because of the programming feature, and the resulting adaptability of the equipment, many different and unique products can be made economically in small batches.

Arc welding is performed by skilled workers who are assisted by a person called fitter. The purpose of the fitter is to organize the work and fixture the parts of the welder. The working condition of the welder is typically unpleasant and hazardous. The arc from the welding process emits ultra-violet radiations which is injurious to human vision. As a result welders are required to wear eye protection in the form of a welding helmet with a dark window. The dark window filters out the dangerous, but it so dark that the welder is virtually blind while wearing the helmet except when the arc is struck.

Other aspects of the process are also hazardous. The high temperature created in arc welding and the resulting molten metals are inherently dangerous. The high electric current used to create the arc is also unsafe. Sparks and smoke are generated during the process are a potential threat to operators. Because of the hazards for human workers in continuous arc welding, it is logical to consider industrial robots for the purpose.

Factors that contribute to the increased rate when robots used in batch production is the elimination of fatigue factor. Robots do not experience fatigue in the sense that human workers do. A robot can continue to operate in the entire shift with need of periodic rest breaks.

Improved safety and quality-of-work environment result from removing the human operator from an uncomfortable, fatiguing and potentially dangerous work situation.

Greater product quality in robot arc welding results from the capability of the robot to perform the welding cycle with accuracy and repeatability than its human counterpart. This translates into a more consistent welding seam; one that is free of the start-and-stop builds up of filler metal in the seam that is the characteristic of many welds accomplished by human welders.

An industrial robot that performs welding must possess certain features and capabilities. Some of the technical considerations in arc welding applications are discussed in the following.

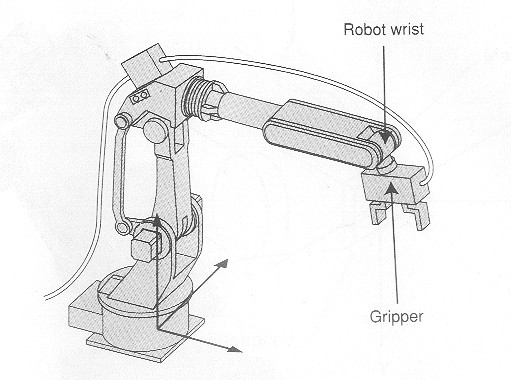

The robot’s work volume must be large enough for the size of the parts to be welded. A sufficient allowance must be made for the manipulation of the welding torch. Five or six degrees of freedom are generally required for arc welding robots. The number is influenced by the characteristics of the welding job and motion capabilities of the parts manipulator. If the parts manipulator has two degrees of freedom, this tends to reduce the requirement on the number of degrees of freedom possessed by the robot.

Continuous path control is required for arc welding. The robot must be capable of smooth continuous motion in order to maintain uniformity of welding seam.

3. PRECISION OF MOTION

The accuracy and repeatability of the robot determines to a large extend for the quality of welding job. The precision requirements of welding job vary according to size and industry purpose, and these requirements should be defined by each individual user before selecting the most appropriate robot.

The robot must be provided with sufficient input/output and control capabilities to work with other equipments in the cell. These other pieces of equipments are automobile fixturing units, conveyors, and parts of positioners. The cell controller unit must co-ordinate the path and path of robot with operation of parts manipulator and the welding parameters such as wire feed rate and power level.

Programming the robot for continuous arc welding must be considered carefully. To facilitate the input of the program for welding paths with irregular shapes; it is convenient to use the walk through method in which the robot wrist is physically moved through its motion path. For straight welding paths, the robot should possess the capability for linear interpolation between two points in the space. This permits the programmer to define the beginning and points of the path the robot is capable of computing the straight trajectory between the points

1. A related problem is that arc welding is often performed in confined areas that are difficult to access, such as insides of tanks, pressure vessels, and ship hulls. Humans can position in to these areas more readily than robots.

2. One of the most difficult technical problems is the variation in the dimensions of the parts in a batch production job. This type of dimensional variations means that the arc-welding path to be followed will change slightly from part to part.

3. Another technical difficulty is the variations in the edges and surfaces to be welded together. Instead of being straight and regular, the edges are typically irregular. This causes variations in the gap between the parts and other problems in the way the pieces mate together prior to the welding process.

Human welders are able to compensate for both these variations by certain parameters in the welding process. Industrial robots provided with sensors to monitor the variations in the welding process and the control logic to compensate for part and weld gap irregularities.

| Are you interested in this topic.Then mail to us immediately to get the full report.

email :- contactv2@gmail.com |